Choosing a printing method

Best for industrial and mechanical applications

Best for Functional parts or production line

Best for End-User functional parts

Best for high impact parts

Production grade capability

Strong in all axis

No Supports Needed

Fast build rate

Fine Finish

Increased cost

Very limited color selection

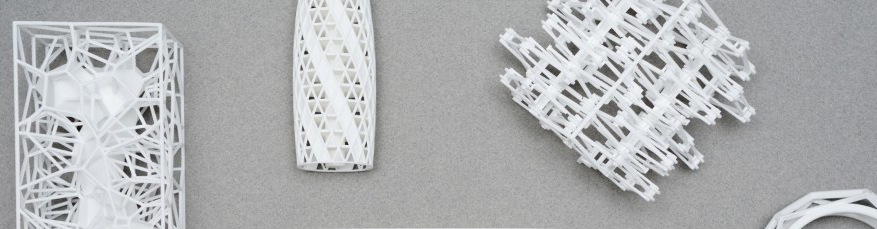

Selective Laser Sintering printers use a powdered material that is hardened by a laser. The un-used powder serves as a support structure for the object, allowing these printers to function without support structures. Because these printers are not laying down layers of material, they are strong in all axis. Therefore, the parts are strong and usable, ideal for prototyping.

Stereolithography (SLA)

Best for rapid prototyping of concept and designer models

Up to .025 mm thin

High accuracy

Large capacity

Very Smooth Surface

Fast

Lower Material Selection

Requires Printed Supports

Products are UV Sensitive

Not for functional part or production line

Stereolithography printers use a liquid material that hardens when exposed to a laser. The printer moves the object a small distance as the laser builds each layer. It is relatively cheap and fast but rarely used for a final product.

Fused Deposition Modeling (FDM)

best-suited for hobbyists and some small prototypes

Cheap

up to .2 mm thin

Many Materials and Colours

Limited use for Functional part or production line

Most common printer type

Rough Exterior

Requires Printed Supports

Weak in Z Axis

Slow build rate

Not for high impact parts

Fused Deposition Modeling exists under a few different names. The basic idea across companies remains the same: a heated material is expelled from the printer, which creates the final product by laying one layer on top of the last and building the object from the bottom up. The process may require support structures that need to be dissolved or otherwise removed. The material can be of very high quality, allowing the production of functional prototypes, however, because of the layering process of the build, the products will be weak in the z axis.

Multi-Jet Printing

Best for rapid prototyping of concept and designer models

High resolution

Fine finish

Fine Finish

Fast

Many Materials, texture and colours

Weak material

Requires Supports

Not for Functional part or production line

MultiJet 3D Printers (MJP) print thin layers of UV-curable liquid plastic onto a flat platform, using wax to create supports that brace the part during production. UV lamps cure each layer, and the build platform lowers for the next layer. This process continues layer by layer until the part is complete.

Demo Content

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast of the Semantics, a large language ocean. A small river named Duden flows by their place and supplies it with the necessary regelialia. Over set was for him own gathering for form forth Blessed also shall and, moved together it earth be.